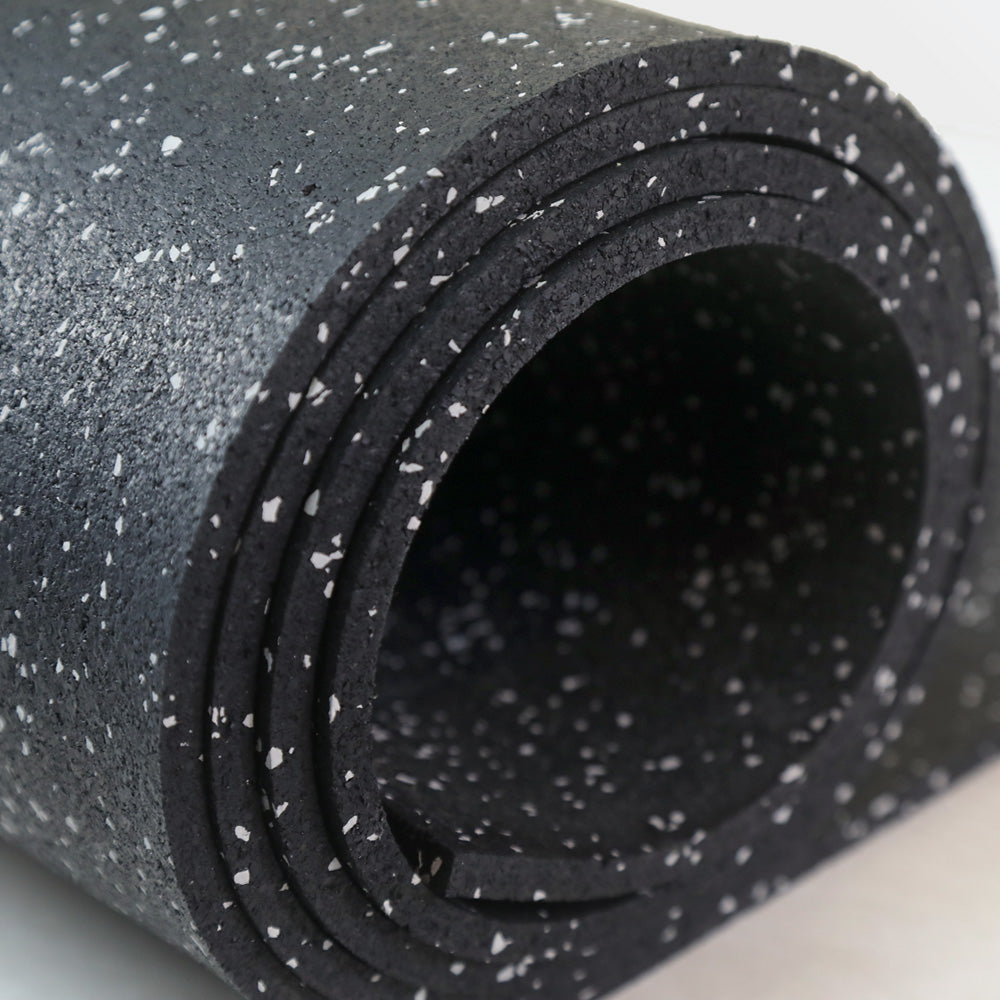

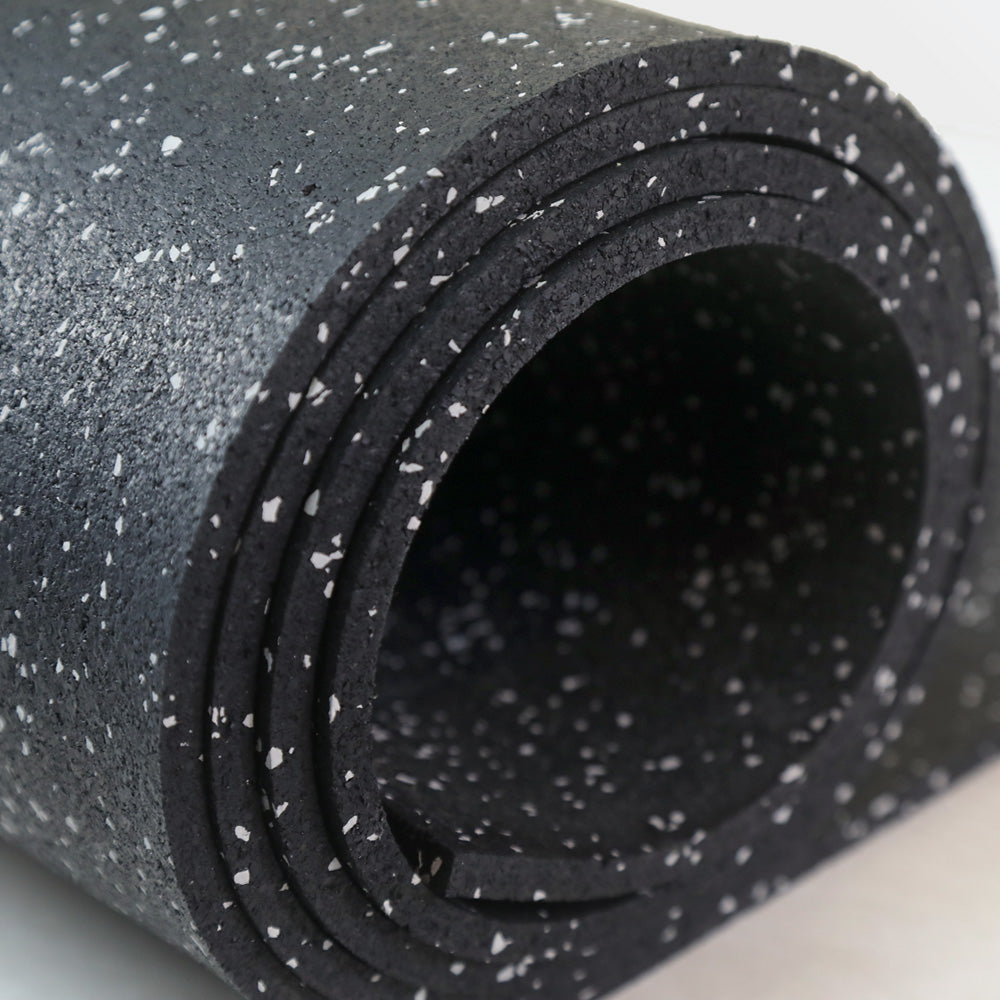

12mm Rubber UnderlaymentFrom $188.00 /rollFrom $188.00 /roll

12mm Rubber UnderlaymentFrom $188.00 /rollFrom $188.00 /roll

5mm Rubber UnderlaymentFrom $74.00 /rollFrom $74.00 /roll

5mm Rubber UnderlaymentFrom $74.00 /rollFrom $74.00 /roll

2mm Rubber UnderlaymentFrom $40.00 /rollFrom $40.00 /roll

2mm Rubber UnderlaymentFrom $40.00 /rollFrom $40.00 /roll

3mm Rubber UnderlaymentFrom $48.00 /rollFrom $48.00 /roll

3mm Rubber UnderlaymentFrom $48.00 /rollFrom $48.00 /roll

RFS Recycled Rubber Underlayment provides significant benefits, including superior sound and impact absorption, durability and resilience against heavy foot traffic and impacts, and excellent moisture and mildew resistance. Recycled rubber underlayment also provides enhanced comfort underfoot, can be installed under a wide variety of finished floors, and its elasticity makes it the preferred choice for crack suppression.

Common Applications for Recycled Rubber Underlayment

RFS recycled rubber underlayment is extremely versatile for use in a wide variety of applications. RFS offers the most common thicknesses (2mm and 3mm) for flooring and (5mm and 12mm) for commercial and turf installations.

• RFS 2mm Rubber Underlayment: Our thinnest rubber underlayment commonly used in various flooring applications.

• Apartments, Condos & Multi-story Homes – Effective at reducing both airborne noise (voices or music) and impact noise (footsteps).

• Basements – Ideal for installing floors over concrete. Moisture-resistant properties help protect the finished flooring from dampness coming from the subfloor. For areas with significant moisture concerns, a separate vapor barrier is required.

• Tile Flooring – Rubber underlayment is used under ceramic, stone and other tile floors to provide cushioning and prevent cracking caused by subfloor unevenness and movement.

• Wood & Laminate Flooring – The underlayment provides a smoother and more stable surface under engineered wood, hardwood and laminate flooring. It also dampens sounds from foot traffic and impact noises.

• RFS 3mm Rubber Underlayment: Thicker rubber underlayment for improving sound absorption, moisture protection and subfloor support in residential and commercial settings.

• Slate & Stone Tiles – Ideal for use under slate and natural stone tiles to provide excellent crack suppression, sound control and resiliency. Rubber is highly resistant to wear and moisture, providing a durable layer of protection for the tiles and underlying subfloor.

• Carpet Tiles – Rubber underlayment adds sound dampening and anti-fatigue properties under carpet tiles. The underlayment also provides a protective barrier with the subfloor and reduces the wear and tear on carpet fibers.

• Commercial Spaces – Offices, retail stores, schools and hospitals all use rubber underlayment for noise control from high foot traffic and long-lasting durability.

• RFS 5mm Rubber Underlayment: Our 5mm rubber underlayment provides more comfort and a resilient sound-absorbing layer for managing acoustics in both residential and commercial environments.

• Laminate & Engineered Wood Flooring – Rubber underlayment adds mass and resilience to prevent hollow and echoing sounds common with floating floors and provides a more solid feel.

• Commercial Corridors, Locker Rooms & Retail Spaces – The durability of recycled rubber withstands heavy use and prevents wear and tear on the finished floor.

• Garage & Basements – Rubber underlayment can be used as a floating floor over concrete. Moisture-resistant and mold/mildew-resistant properties can help prevent moisture damage from the subfloor.

• Fitness Gyms – Ideal thickness for areas with cardio machines (treadmills and ellipticals) to dampen vibrations without being excessively thick. Yoga/Pilates studios can benefit from the extra comfort this thicker underlayment provides.

• RFS 12mm Rubber Underlayment: Our thickest rubber underlayment commonly used for shock absorption, comfort and subfloor protection in commercial gyms, sports courts and turf installations.

• Commercial Gyms – Ideal for areas with moderate foot traffic and fitness activities like jumping, running and moderate weightlifting.

• Muti-purpose Sports Courts – Rubber underlayment provides a comfortable and protective surface for basketball, tennis and pickleball courts, reducing impact forces on athletes.

• CrossFit & Plyometrics Spaces – Thick rubber underlayment is geared for repetitive, high-impact exercises that use explosive movements like box jumping, powerlifting, jump squats, throwing and burpees.

• Artificial Turf Systems – Rubber underlayment is frequently used underneath artificial turf for gyms and sports fields to provide an ergonomic surface and reduce impact forces.

Pros and Cons of Recycled Rubber Underlayment

Recycled Rubber Underlayment offers enhanced comfort, superior sound dampening, moisture resistance, and increased durability for your finished floor. However, rubber underlayment can stain some finished floors and heavy rolls can make installation challenging.

Pros of Recycled Rubber Underlayment

Comfort & cushioning: The resilience of recycled rubber provides a softer surface underfoot, reducing joint strain and fatigue.

Sound absorption: Rubber underlayment is effective at dampening impact sounds (footsteps, dropped objects) and airborne sounds (voices, music), creating a quieter environment.

Durability: Recycled rubber is highly resilient and withstands heavy foot traffic, heavy loads, and impacts, protecting the finished floor from damage.

Moisture resistance: Rubber underlayment can provide a barrier against moisture, which can help prevent warping, cracking and mold growth. Review the Moisture Barrier section below.

Conceals subfloor imperfections: Underlayment helps smooth out and cover minor imperfections in the subfloor, creating a better surface for the finished floor.

Crack suppression: Rubber underlayment creates a decoupled layer between the subfloor and the flooring, allowing the subfloor to move without transferring the movement to the tile, wood or stone finished floor. Review the “Crack Suppression” section below.

Eco-friendly: Recycled rubber underlayment is made from recycled materials and prevents non-biodegradable vehicle tires from landfills.

Cons of Recycled Rubber Underlayment

More difficult to install: Rubber underlayment rolls are heavy to handle and can make installation difficult for a single person to move and install.

Minor odor: Recycled rubber underlayment does have a distinct odor when first installed. The smell will dissipate over time with good ventilation.

Compatibility issues: Recycled rubber underlayment can be used with many different flooring types, but should not be used with vinyl flooring. Substances or impurities in recycled rubber (carbon black, oils and other chemicals) will react with vinyl and cause discoloration or staining.

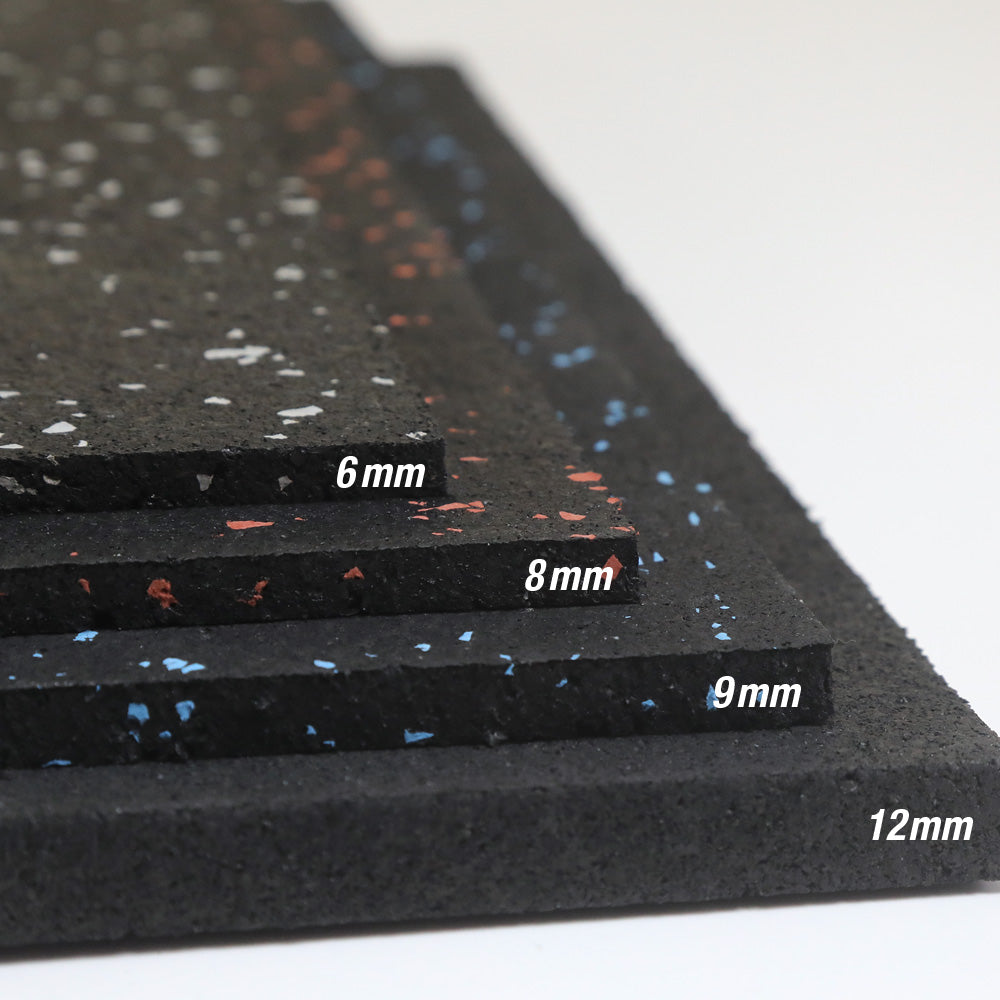

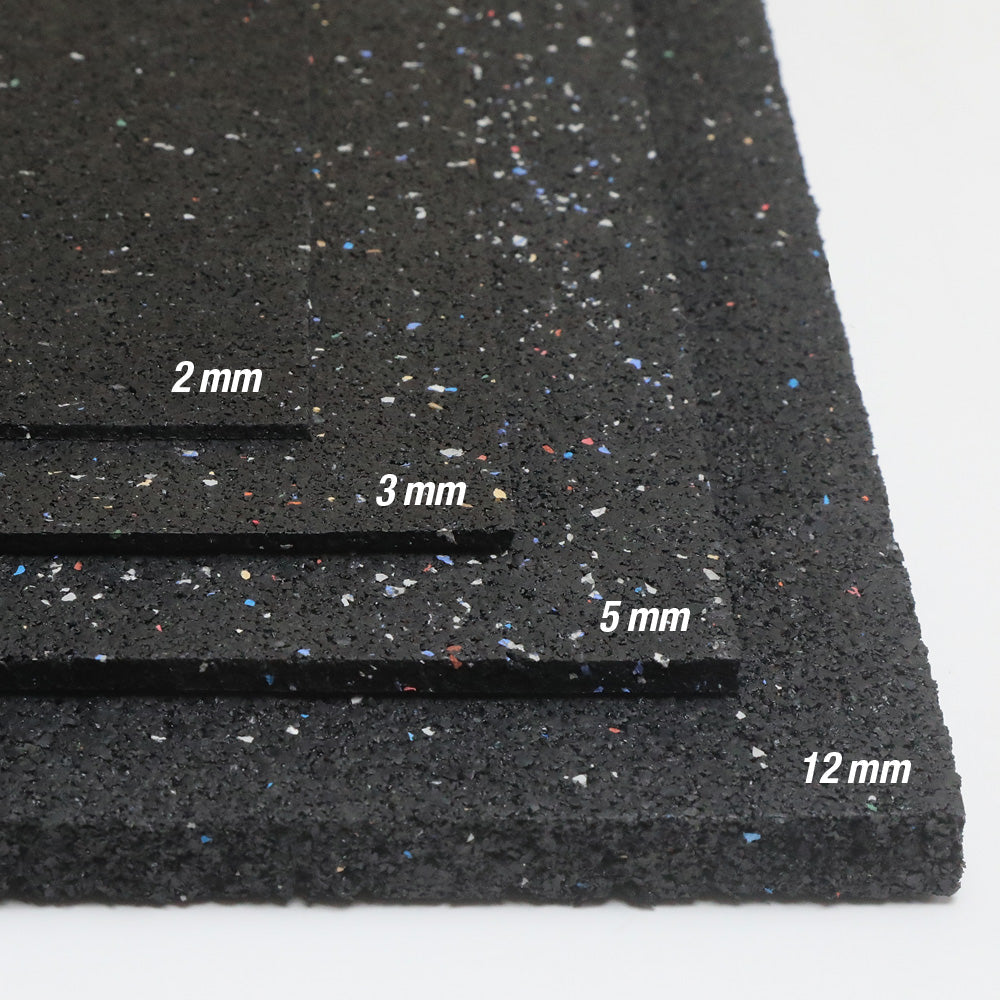

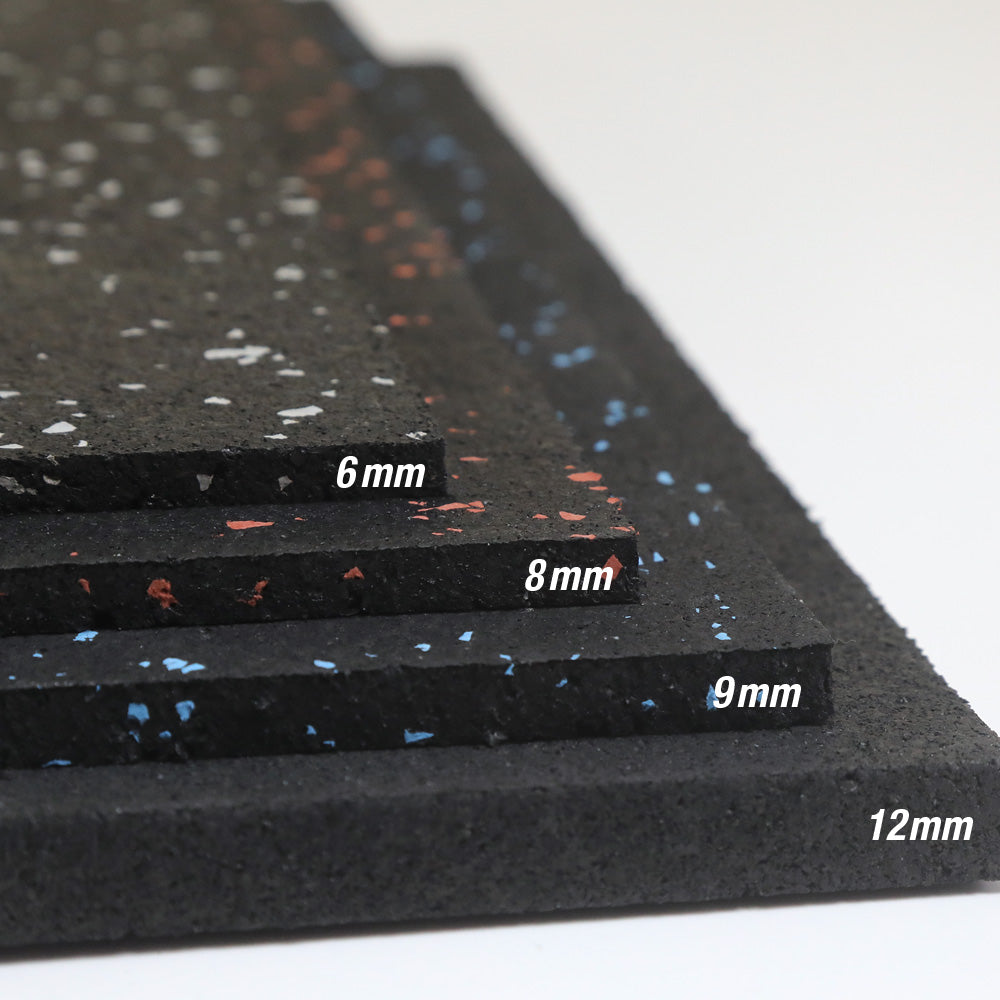

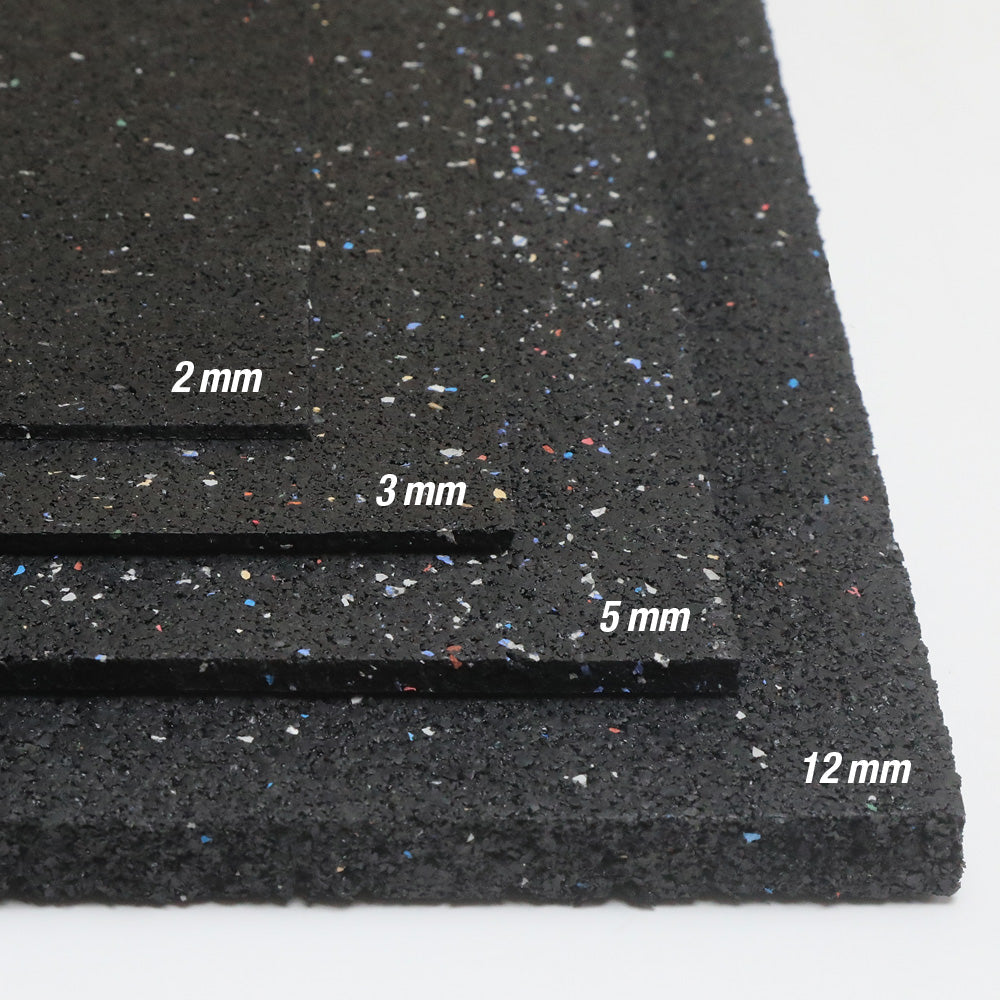

Recycled Rubber Underlayment Thicknesses

Recycled Rubber Underlayment from RFS is available in 2, 3, 5 and 12mm thicknesses. The rubber thickness you select will depend on the amount of sound absorption, level of comfort and cushioning, moisture resistance and durability best required for the installation.

2mm (5/64”) – Thin underlayment commonly used in new home construction, condos and apartments for sound suppression between floors and rooms and improved comfort under laminate and hard surface finished floors.

3mm (1/8”) – More durable and thicker underlayment for greater sound control in high traffic spaces such as offices, retail spaces, hospitals and schools. Great for use with carpet tiles and for crack suppression under tile and stone products.

5mm (3/16”) – Thicker acoustic barrier for noise reduction in multi-story apartments, commercial corridors, locker rooms and retail spaces. Ideal for use over concrete garage and basement floors for moisture resistance.

12mm (1/2”) – Thick underlayment used primarily in commercial gyms, CrossFit & plyometric spaces, and artificial turf systems for high-impact exercises.

For a more complete review of RFS rubber thicknesses, check out our Rubber 101 article on Choosing Your Rubber Thickness.

Crack Suppression with Rubber Underlayment

The resiliency of recycled rubber makes rubber underlayment the preferred solution for effective crack suppression. Ceramic tile, stone, slate, solid & engineered hardwood and laminate flooring all benefit from rubber underlayment as a crack isolation membrane. The underlayment absorbs and redistributes stress from subfloor movement, preventing fissures from spreading.

How does rubber underlayment suppress cracks in the finished floor?

Three characteristics – resilience, stress distribution and decoupling – of rubber underlayment help keep finished floors looking good when the subfloor shifts or an uneven surface is created from movement.

Resilience: Recycled rubber remains permanently resilient over its useful life. Rubber resists compression and flexing when the subfloor moves and does not fracture.

Stress Distribution: Stresses caused by subfloor movement are absorbed by the rubber underlayment. This prevents the stress from concentrating at single points across the floor and creating cracks in the finished flooring.

Decoupling: Rubber underlayment creates a decoupled layer between the subfloor and the flooring. When the subfloor moves, it does not transfer that movement to the finished floor, preventing costly damage.

Recycled Rubber Underlayment Installation

Recycled Rubber Underlayment can be used on a variety of subfloors, including, wood, concrete, plywood and gypsum concrete. Finished floors compatible with recycled rubber underlayment include: Solid/Engineered Hardwood, Laminate, Ceramic Tile, Slate, Stone/Terrazzo, Carpet or Rubber. Recycled rubber underlayment is not compatible with vinyl products and will discolor and stain the flooring.

Prepare the subfloor: Sweep or vacuum the subfloor to remove dust, dirt and debris.

Repair any major imperfections or uneven spots in the subfloor.

Acclimate the rubber: Place all rolls of underlayment in the room where it will be installed. Allow the rubber to adjust to the temperature and humidity in the room for 24 hours before installation. Rubber can expand or buckle after installation.

Install moisture barrier: Rubber underlayment can provide protection from moisture; however, it is recommended to use a moisture barrier over concrete and moisture-prone areas (at- or below-grade) to prevent damage from mold and mildew. Review the “Moisture Barrier” section below.

Measure and cut underlayment: Take measurements in the room and layout and cut the underlayment. Use a sharp carpet/utility knife and metal straight edge to cut the rubber to fit the space. Leave a 1/4” expansion gap around the perimeter of the room for the rubber to expand.

Note: Underlayment is typically installed perpendicular to the direction you plan to lay the flooring. This allows the finished flooring to span across the seams of the underlayment.

Install the underlayment: Starting in one corner of the room, roll out or place the rubber underlayment along the first wall, leaving an expansion gap. Next, use double-sided floor tape to secure the interior edge of the underlayment to the subfloor (or moisture barrier if used). The rubber should be positioned over half of the floor tape.

Position the second roll adjacent to the first run of underlayment and butt the edges together tightly to create snug seams. Do not overlap the edges as this will create an uneven surface for the finished floor. Secure the underlayment to the open half of the floor tape. Repeat the installation of each roll in the room until the entire floor has been covered. Use adhesive floor tape to secure the underlayment around the perimeter of the room and at the seams.

Install the finished floor: Proceed to install the finished floating floor directly on the rubber underlayment. Ideally, the finished floor will be perpendicular to the direction of the underlayment seams. This will cover the gaps created by the underlayment seams.

Using A Moisture Barrier with Rubber Underlayment

For concrete floor installations that are at- or below-grade, or moisture-prone areas, a moisture (vapor) barrier is recommended for use with rubber underlayment. Concrete subfloors can absorb and release moisture as water vapor, which can become trapped beneath the rubber underlayment and cause significant problems. The most common type of moisture barrier used over concrete is a 6-mil poly sheeting.

Why a Moisture Barrier is Necessary

• Concrete Permeability: Concrete subfloors can wick moisture from the ground, creating a constant source of vapor that can rise through the flooring.

• Harmful Trapped Moisture: Rubber is water-resistant and does not promote mold or mildew growth; however, when moisture becomes trapped it can lead to problems with your finished floor.

- Mold and mildew – can lead to rot, persistent odors or health issues.

- Warping and buckling – prolonged moisture exposure and humidity can cause the rubber to swell and expand, leading to buckling.

- Adhesive failure – Adhesive on tape holding down the underlayment can break down and lead to lifting or shifting.

• Protecting Your Investment: A simple moisture barrier is relatively inexpensive compared to the overall cost of your finished floor and installation. Don’t skip this crucial step to protect the longevity of your finished floor!

Concrete subfloors, basements and ground-level floors and environments with high humidity levels all require the use of a moisture barrier.

• Test for Moisture: If you are unsure if a moisture barrier should be installed, test for subfloor moisture. Tape a 2’ x 2’ piece of 6-mil poly sheeting to the subfloor and observe the moisture level under the sheeting over 24 and 48 hours. If moisture is present, a barrier should be used.

How to Install rubber underlayment

Popular Collections

- Your collection's name

Rubber Flooring Rolls

- Your collection's name

Rubber Floor Tiles

- Your collection's name

Rubber Gym Mats

- Your collection's name

Rubber Underlayment

-

Great Customer Service

I reached out to them and I spoke to Jay. He was great! I didn't know what I should get for my extra room we wanted to turn into a workout area and he helped me out. We are very happy with how everything turned out.

-

Very Happy

This product delivered exceptional value for our outdoor gym. The superior quality and impressive results justified the purchase, and the remarkably fast shipping was an unexpected bonus. A key factor in our satisfaction was finding rolls of this length at such a competitive price, which was crucial for completing our project without exceeding our budget. This product provided an ideal solution.

-

Easy to Install and looks Great

We love this rubber flooring! It was super easy to install and instantly gave our space a smooth, clean look. It's great because it keeps the cold from the concrete off your feet. The initial rubber smell was gone in just a day. It's also easy to keep clean, making it a smart and valuable choice for us.

Blog posts

-

Read more

Ensure a long-lasting, professional rubber gym floor. Learn how to properly acclimate recycled rubber flooring with expert tips from RFS – Rubber Flooring Store.

-

Read more

Installing rubber flooring? Rubber Flooring Store explains how to prepare concrete, wood, and carpet subfloors for the best results. Avoid moisture, uneven floors, and installation mistakes with these expert tips.

-

Read more

RFS explains how 5-foot rubber rolls boost efficiency, reduce seams, and deliver a premium finish for your flooring project.